UM students’ research on Heat Transfer and Pressure Drop Characteristics of 3D Printed Tubes win the best paper awards at the International Symposium on Thermal-Fluid Engineering

澳大學生3D打印管道之傳熱及壓降研究於國際研討會奪最佳論文獎

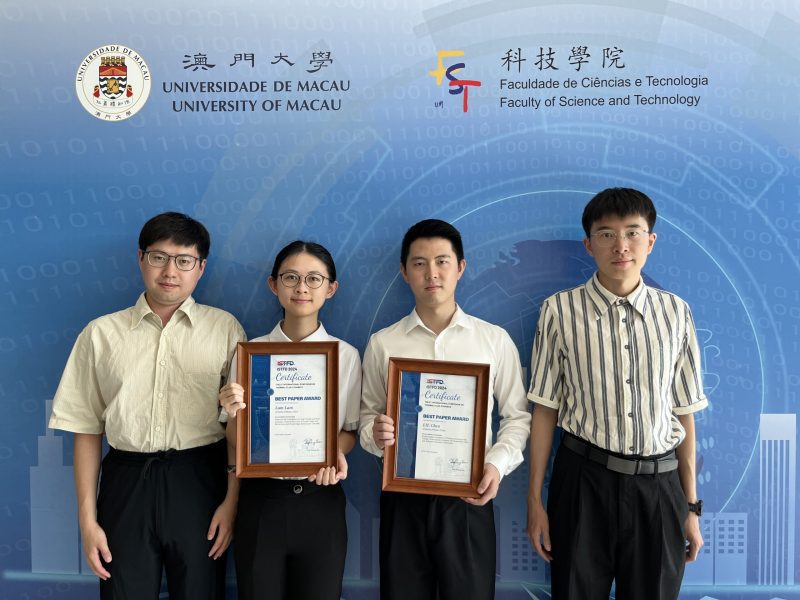

(左起)楊伊凡、林霖、陳佳航和倪澤豪

(左起)楊伊凡、林霖、陳佳航和倪澤豪

(From left) Yifan Yang, Lam Lam, Jiahang Chen, and Zehao Ni

|

|

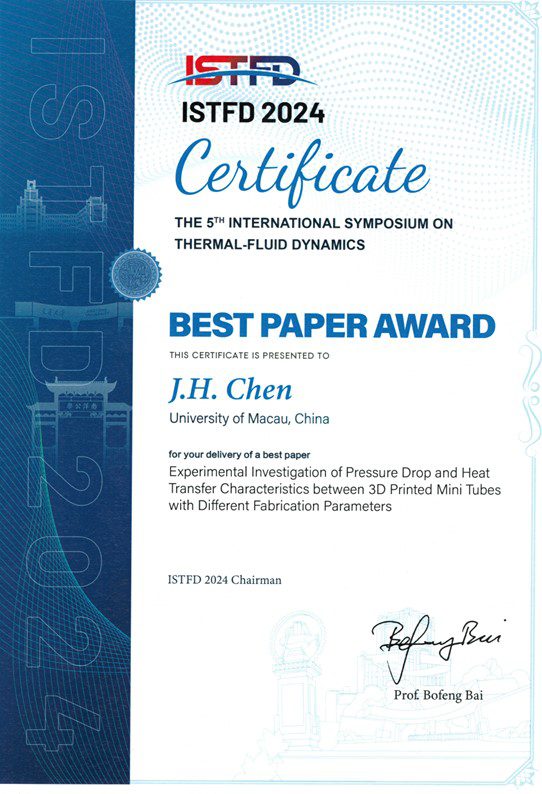

Best Paper Award (Chen Jiahang and Lam Lam) 最佳論文獎 (陳佳航及林霖)

Mr. Jiahang Chen, a doctoral student, Mr. Yifan Yang, a doctoral student, and Ms. Lam Lam, a master student, from the Department of Electromechanical Engineering (EME), Faculty of Science and Technology (FST), University of Macau (UM), have won the best paper awards at the 5th International Symposium on Thermal-Fluid Dynamics (ISTFD 2024), which was hosted by Xi’an Jiaotong University (XJTU). Experts at the symposium fully recognized the effort and achievement of the research team of UM. This year’s symposium gathered over a hundred scholars and researchers from around the world, featuring more than 100 oral and poster presentations, 9 plenary lectures, and 20 thematic lectures, all led by distinguished researchers in the field of thermal fluids, showcasing the most advanced knowledge and technology in the domain.

In the symposium, Mr. Jiahang Chen represented the research group to present a paper titled “Experimental Investigation of Pressure Drop and Heat Transfer Characteristics of 3D-Printed Mini Tubes using Different Fabrication Parameters”. As an advanced manufacturing technology, Selective Laser Melting (SLM) 3D printing technique, which was one of the additive manufacturing methods, could be used to print sophisticated and small-sized heat exchangers with large heat transfer areas so it has attracted high attention in the thermal engineering community in recent years. Due to the differences in inside wall surface characteristics between 3D-printed tubes and traditional tubes, the research team experimentally compared the pressure drop and heat transfer characteristics of 3D-printed stainless-steel tubes under different fabrication parameters. The results showed that the friction factors and heat transfer coefficients of the 3D-printed tube were directly affected by different printing parameters.

Ms. Lam Lam represented the group to present a paper titled “Experimental Investigation on Heat Transfer and Pressure Drop Characteristics of 3D Printed Tubes with Semicircular and Round-edge Semicircular Channels”. A pair of semicircular channels and rounded semicircular channels were manufactured by 3D printing methods to imitate the different channels in printed circuit heat exchangers (PCHE). The pressure drop of the two tubes was measured and compared under isothermal and uniform heat flux boundary conditions. The research results of this study provide a fundamental understanding of the semicircular channel with or without round-edge inside the PCHE.

The two research projects were supervised by Prof. Lam Mou Tam, Professor of Department of EME. Mr. Jiahang Chen’s research project is sponsored by the Science and Technology Development Fund (FDCT) and the National Natural Science Foundation of China (NSFC). Ms. Lam Lam’s research project is sponsored by the Macao Science and Technology Development Fund (FDCT) and the Ministry of Science and Technology of the People’s Republic of China (MOST).

澳門大學科技學院機電工程系博士生陳佳航、博士生楊伊凡及碩士生林霖於西安交通大學主辦的第五屆熱與流體動力學國際研討會 (ISTFD 2024)奪得了最佳論文獎。澳門大學研究團隊的努力和成果得到專家評委們的充分認可。熱與流體動力學國際研討會作為熱與流體力學領域重要的國際研討會之一,致力於推動熱與流體力學及相關新興、前沿和跨學科的知識和技術發展。今年的盛會匯聚了來自世界各地的百餘位學者和研究者,100多場口頭及海報演講、9場全體講座和20場主題講座,由熱流體領域內的杰出研究人員主持,展示了該領域最前沿的知識和技術。

研討會上,陳佳航代表研究團隊報告了論文題為《不同製造參數下3D打印微型管壓降和傳熱特性的實驗研究》的論文,增材製造作為一種先進的製造技術,如選擇性雷射熔化(SLM)的3D打印技術,能打印出體積小但傳熱面積大的特殊熱交換器,在近年引起了熱力工程界高度關注。由於打印的管道和傳統管道在金屬表面特徵上存在差異,因此,研究團隊在等溫和非等溫的邊界條件下,利用實驗方法比較不同打印參數下的3D打印不鏽鋼管的壓降和傳熱特性,實驗結果顯示3D打印不鏽鋼管的摩擦因子與熱傳系數會受到不同列印參數的影響而產生變化。

林霖代表團隊報告了題為《3D打印半圓通道和圓角半圓通道的傳熱及壓降特性實驗研究》的論文,研究採用3D打印方法製造了半圓形通道和圓角半圓形通道,以模擬印刷電路熱交換器(PCHE)的不同通道,在等溫和均勻熱通量邊界條件下測量並比較兩個理想的半圓形通道和圓角半圓形通道之間的壓降差異。研究結果為PCHE帶或不帶圓角的半圓形通道提供了傳熱及壓降特性的基礎参考資料。

兩個研究項目皆由機電工程系譚立武教授指導,陳佳航的研究課題是由澳門科學技術發展基金(FDCT)與國家自然科學基金委員會(NSFC)聯合資助,林霖的研究課題則由澳門科學技術發展基金(FDCT)與國家科技部聯合科研(MOST)聯合資助。